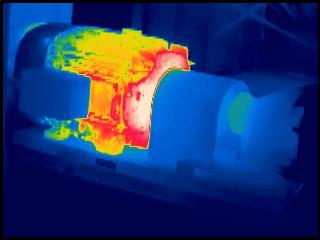

When any mechanical device is in operation, heat is generated.

Forces such as misalignment, friction, improper lubrication and inaccurate belt tension cause excessive heating.

What can we detect?

We can detect misalignments is coupled equipment, excessive friction, over/under lubrication of bearings, over/under tension of belted systems and defective equipment.

Thermal imaging can detect potential catostophic failures due to overheating weeks in advance.

Conditions:

The system must be under load, and we need a clear line of sight to the object being imaged.

The brilliant part about thermal imaging on mechanical (and electrical) components, is there is no interuption to the service needed, it’s non-contact and can be performed remotely.

Components we are certified to inspect:

Motors & Generators – Electrical connections, Rotor & Stator, Bearings, Couplings

Rolling Element Bearings

Belts

Gearboxes

Thermal imaging is the fastest way to detect exceptions that are not visible to the human eye.

Contact us today for a complete inhouse infrared ‘predictive’ inspection of the mechanical components in your business today!