Our company continues to grow strongly in the electrical thermal imaging industry in New Zealand. We have imaged 1000’s of switchboards across NZ, namely in the agricultural, food production, cold storage, shipping and offshore oil sectors.

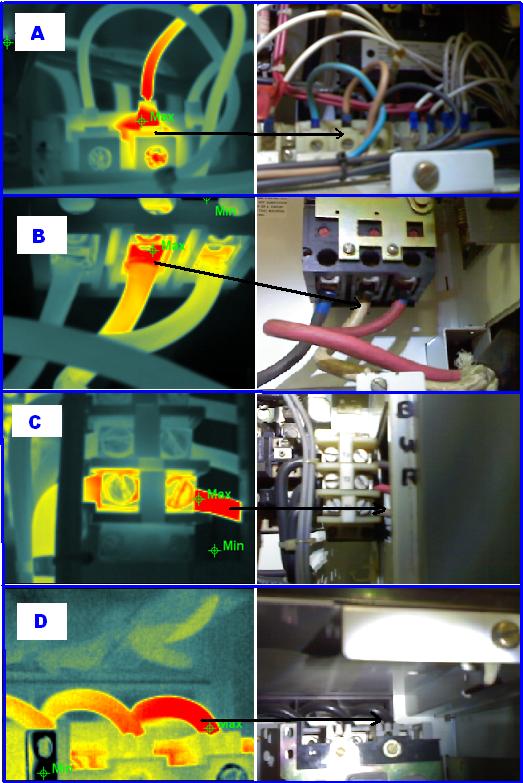

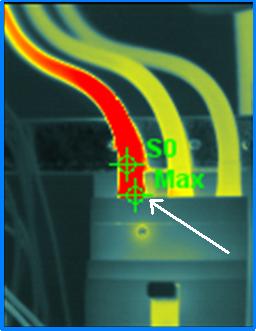

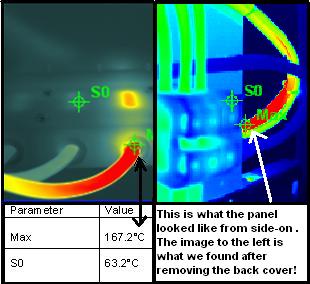

We were recently hired to complete the thermographic survey of a large vessel while in the process of siesmic mapping of the ocean floor off the east coast of the South Island, NZ in search for potential oil fields. For optimal results, all infrared surveys should be carried out under maximum load where possible, and in this situation the ship was in transit at the time of inspection. This also allows the ships engineers/electricians to switch over to back up systems so all associated electronics can be accurately infrared imaged during the same survey.

We are an experienced thermography company in NZ, qualified for infrared inspections on Switchboards and Mechanical Components in all types of facilities.

Here is a typical list of components we apply thermal imaging surveys to on ships, and all onshore operations:

- Main Engines

- Generators

- Main Switchboards

- Emergency Switch Gear

- Main Propulsion Units

- MCC Boards

- Motor Junction Boxes

- We carry out thermal imaging of all Distribution Boards, such as 24V, 230V, 400V, 440V… right up to 11KV and everything in between.

- Infrared imaging of Transformers, Compressors, Automation, Motors, Propulsion Drives, Cabling etc.

If you are looking for a reliable infrared company in NZ with an excellent track record for providing prompt service at short notice, along with compliant thermal imaging reports accepted by insurance companies who now require AS/NZS 3019:2007 (electronic installations – Periodic Verification) standards, then call us today to discuss your project and a free quote over the phone based on requirements.

We are certified thermographers with current medicals, HUET, BOSIET and constantly updated infrared cameras and technology. Call today to find out more.

>

>