Here is exactly why a regular thermographic survey of company electrical systems is so important.

I inspect switchboards for many different private, commercial and insurance companies right across NZ, but the latest infrared electrical inspection in particular was quite interesting… for all the wrong reasons (In my opinion).

When you have a 24/7 operation, a thermal imaging survey every 6 months should be strictly enforced… not every 9 or 12 months. Recently, I was called out to an oil rig that had just experienced a fire in one of the main switchboard rooms nine months after the first thermographic inspection was carried out. If this company had maintained a strict policy for every 6 months, then this hot spot/fire hazard would have been picked up well in advance. To make matters worse, it was at 1:00am in the morning when the alarm went off. The crew of 40+ workers woke up to a fire on a ship full of oil. Not good. Put yourself in that position!

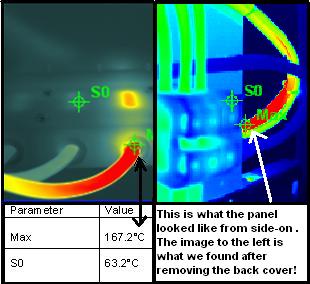

Upon the re-inspection of the surrounding switchboards in the same electronics room, I found another huge hot spot caused by a loose connection on the back of a sea water injection pump. The temperature at the connection was 167 degress! Here’s the photo…

This was a large offshore operation, so it was easy enough to shut this pump down and switch to the back up pump. It didn’t end there…

Next… I was thermal imaging a lighting panel in the engine room, and suddenly a glowing 92 degrees hot spot was coming off a 20amp breaker. Further testing showed 27 amps running through. It turns out the breaker and cables were under rated. One fire and two potential fires found within 3 weeks… this is not a record to brag about… but it can happen to any company who turns a blind eye to the importance of electrical system faults.

Remember, it only takes one hidden loose connection to potentially ‘bring the house down’. This is why some insurance companies now require thermal imaging prior to issuing a policy.

If you are considering a thermal imaging thermographic inspection, then now is the time. As the above company recently found out, it can turn out to be very expensive if you just ‘hold off’ for a few weeks or months… or not at all. More electrical fault photos here