When it comes to protecting your assets, using an experienced thermographic survey company that pays attention to detail should be your first choice.

We specialise in infrared thermography… that’s all we do.

We have offshore oil tankers, publically listed NZ companies and overseas clients using our service on a repeat basis, so we are 100% confident you’ll also be satisfied with the results and reporting standards we can deliver your company aswell.

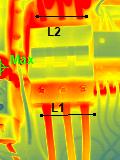

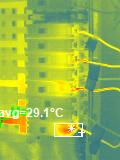

If you own a company that has multiple electrical switchboards that haven’t had a thermographic survey in the past, then it may be a wise move to have a check up. We are consistantly finding large electrical faults in very important distribution switchboards that could have caused major shutdowns if not picked up early, so don’t wait for it to happen… prevent it instead. In the event of an electrical fire, our thermographic report could make the difference between your insurance company paying out or not!

Click here to read more about our electrical thermography service.