Our company is now specialising in electrical thermal imaging surveys across NZ, and the more switchboards we inspect, the more we begin to wonder why there hasn’t been more electrical fires!

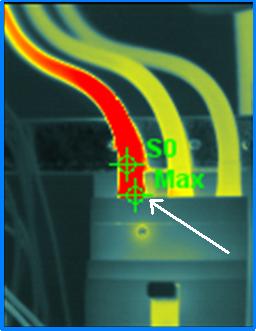

Here’s a photo of a switchboard that was only inspected 6 months earlier… a perfect example of why routine preventative maintenace is so important. This photo is of a hot spot around the termination point of 160 amp breaker. The 3 phases were all running at 73amps, yet the red phase was running 50% warmer. This is called an anomaly requiring further investigation:

We have now detected so many faults during routine infrared scans of electrical systems, we can see why our clients are now switching to bi-annual thermographic surveys rather than annually. The fact that our biggest NZ clients use our service on a repeat basis is testiment to the value of infrared thermography surveys in general, and to the service we offer.

The look on the site managers face when a hot spot is detected which is very close to causing a fire, is one of relief… relief that they decided to get a thermographic inspection if the first place. Situations like this makes them quickly understand the value in what thermal imaging surveys can offer.