Infrared thermography is a fast way to determine electrical faults, no matter what the complexity of the component is.

Recently I conducted a complete thermal imaging electrical inspection on an offshore oil rig. You can only imagine how important it is to prevent any type fire breaking out on a ship full of oil! The main benefit of electrical thermography is that the infrared camera can detect hot spots (and alot more) in an instant… the human eye will not see any of these anomalies in most cases.

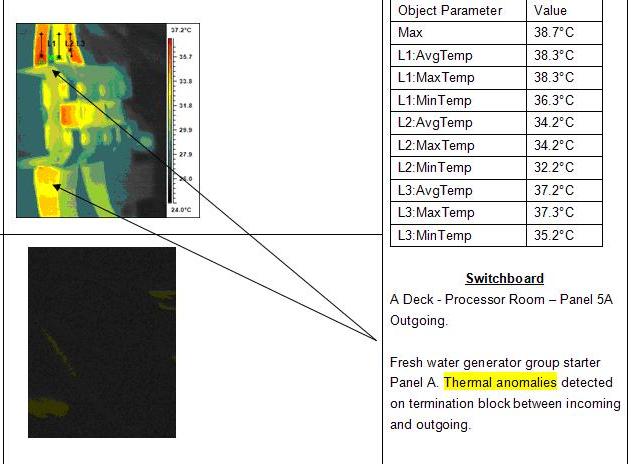

No matter how switched on your on-site electrician or maintenance officer is, they simply won’t see what infrared can see… it’s impossible. In the case of this particular job, the thermography inspection yeilded 18 faults. Here is an example of just one electrical fault I found on board…

NZ Commerical Clients: NZ District Councils – Publically Listed NZ Companies – Banks – Shopping Center Chains – Shipping Companies – Mining Companies – Oil Companies – Offshore Oil Rigs – Marine Services – Production Companies – Engineering Companies – Electrical Contractors – Leisure Centers – and many others (Specific names available upon request).

We conduct electrical thermography inspections throughout New Zealand, so feel free to call today for a quote based on your company circumstances.